COLOUR SORTERS

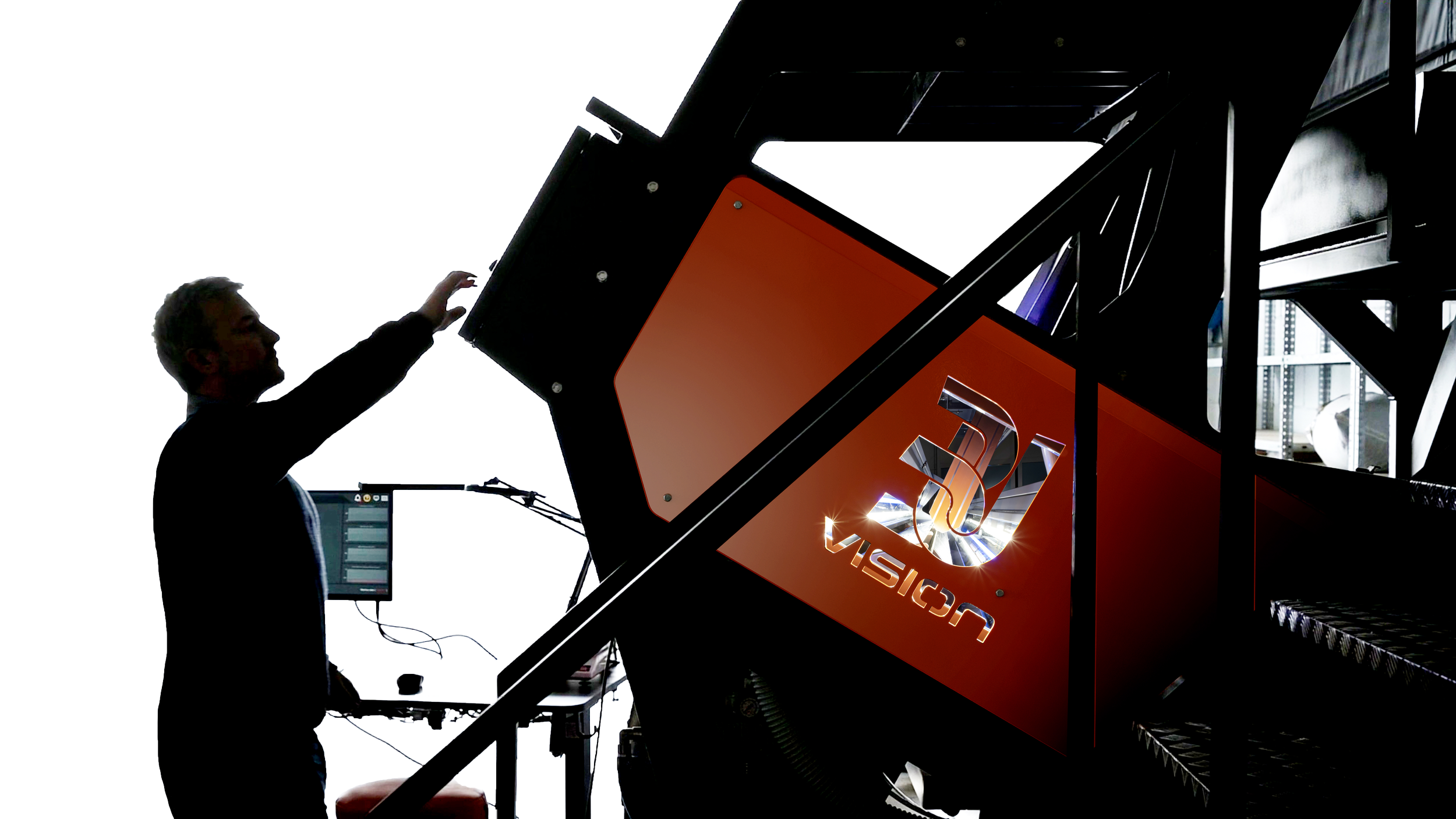

To deliver the best solution, we have partnered with 3U Vision, the industry leader in advanced optical sorting technology. Their state-of-the-art Optical Sorters set the benchmark for precision, efficiency, and innovation, ensuring optimal performance for your business.

As part of our exclusive partnership, we provide worldwide service and support for 3U Vision machines. Their cutting-edge remote-controlled service allows for instant troubleshooting, while expert on-site support is available whenever needed.

For more information, contact us at info@westrup.com.

OPTICA HD

The machine's innovative design ensures perfectly aligned views, significantly improving defect detection in similarly colored products with varying infrared responses, such as foreign bodies or inorganic flaws.

Advantages of the Optica HD includes:

Enhanced Defect Detection

4-Wavelength System

Flat Spectrum LEDs

RISE-UP System

IOT & Remote Support

User-friendly software

Uniform flow control

FENIX

The Fenix Optical Sorter revolutionizes industrial automation with advanced image processing, ensuring precise monitoring, real-time error detection, and immediate intervention.

Advantages of the Fenix includes:

Custom-Designed Ejectors

RISE-UP System

Signal Equalization System

Automatic Air Pressure Regulator

Vibrator Speed Control and Equalization

Sanitary Coated Chutes

Integrated Remote-Service System

Download product sheet for FENIX

THE MINIS

The Optica Mini and Fenix Mini are the perfect choice for businesses seeking high-precision, efficient air usage, and scalable sorting solutions in a compact design.

Advantages of the Minis includes:

Single-sensor design

Efficient air usage

Remote servicing

High performance

IoT and Industry 4.0 capabilities

RISE-UP System

-

3U Vision is an italian based company working with advanced vision systems, specifically with optical sorting machines.

The company has more than 40 years experience with CEO Antonio Uzzo leading the technologically strong company.

Learn more about 3U Vision: https://www.3uvision.com/english/mission

-

An optical sorter is doing a sorting after color, reflection or form.

-

First, the optical sorter must be trained to distinguish between defective and high-quality seeds. This process begins by manually identifying defective seeds and impurities, which the sorter captures in multiple images from all angles. Similarly, images of high-quality seeds are also taken for reference.

After this, the optical sorter can accurately differentiate between defective and good seeds, as well as remove impurities, forgien material and ergot.

The product is then fed into multiple channels based on capacity. Each channel is equipped with cameras to detect defects. Any identified defects are precisely removed using an air nozzle.

-

An optical sorter is an efficient machine used in the processing line together with air and screen cleaners, indented cylinders, and gravity tables. It ensures exceptionally high purity levels while minimizing the loss of good seeds.

Unlike other machines, an optical sorter can distinguish and separate seeds that are identical in size and shape but differ in color, providing a level of precision that other sorting methods cannot achieve.